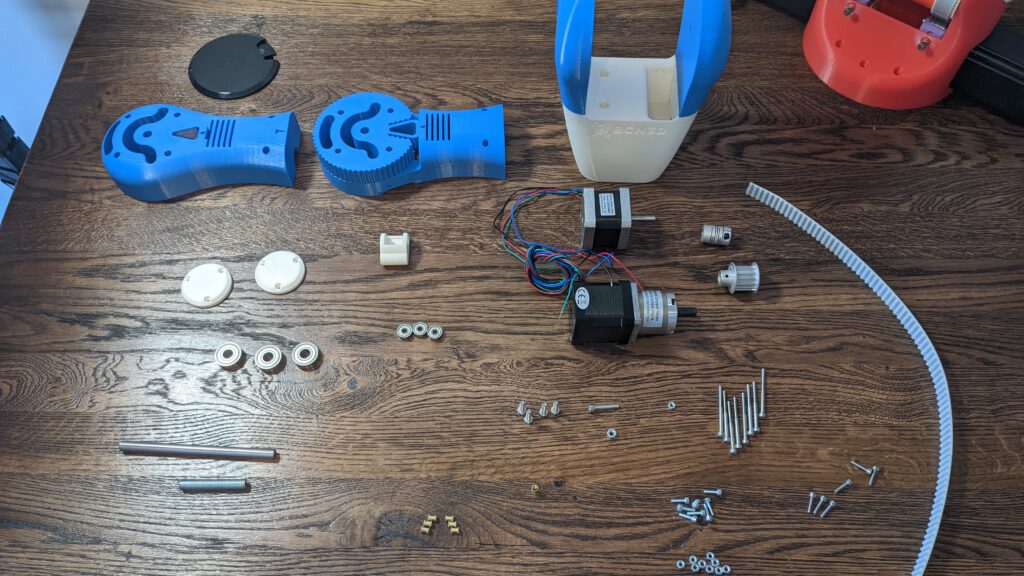

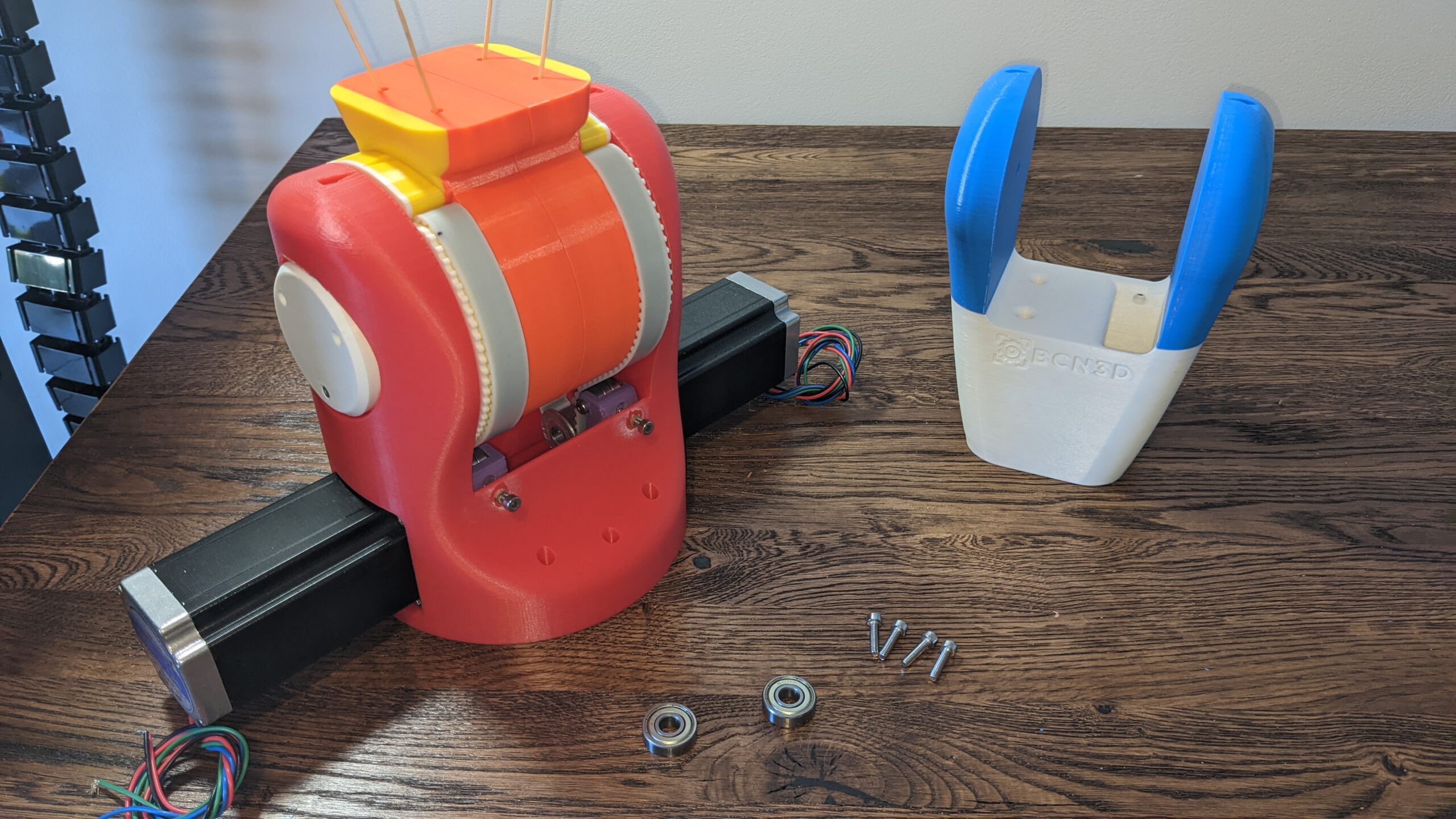

The 3rd module does not come with bigger issues. It was quite convenient to set everything up. In the last part, I made a mistake where I glued the M3 brass inserts into the hole. Now I knew that there are heat inserts. And with some head, it is straightforward to install them. Although I have to glue the M4 inserts in place because the inserts are too small for the hole.

Preparation

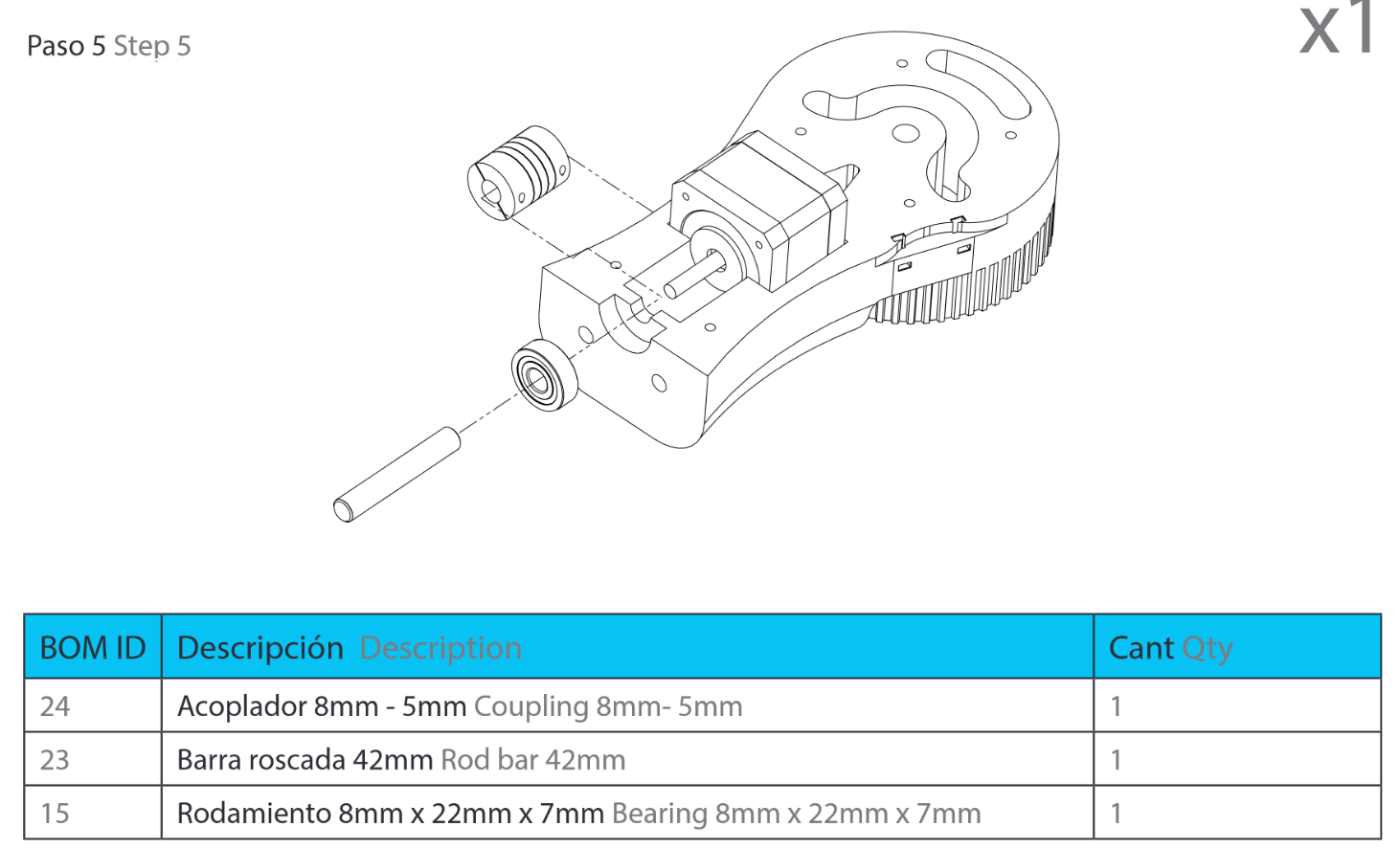

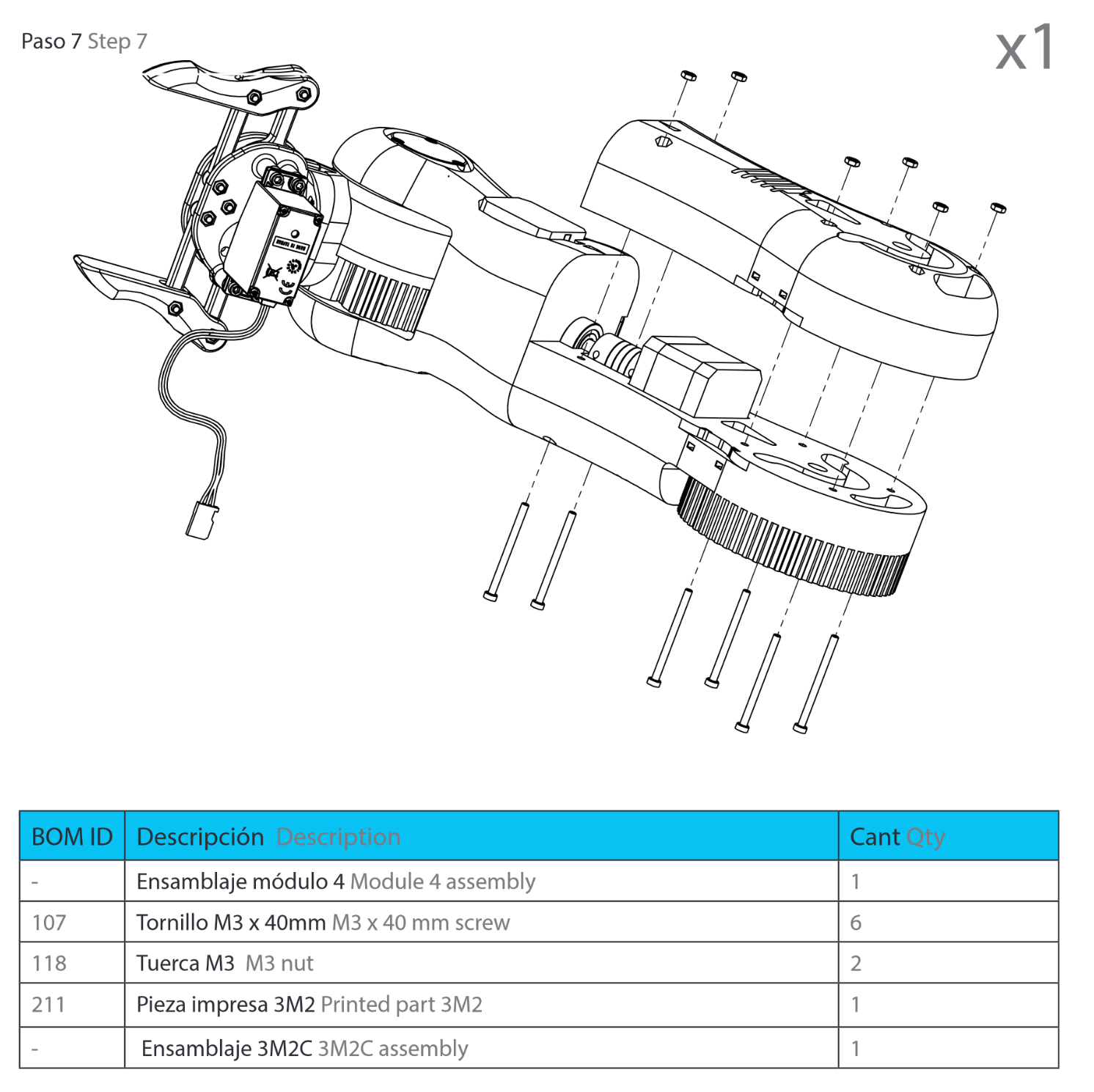

BOM for part 3

Tools

- HX4 Screw driver

- HX2 Screw driver (for the pulley)

- Solder Iron

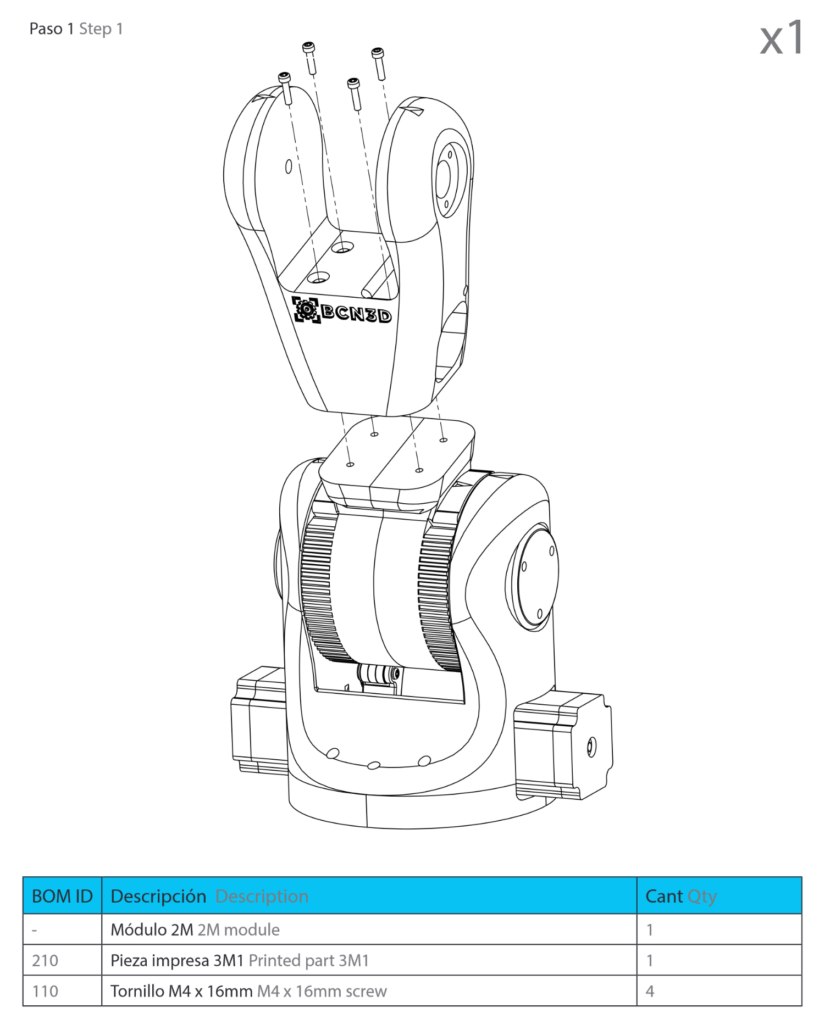

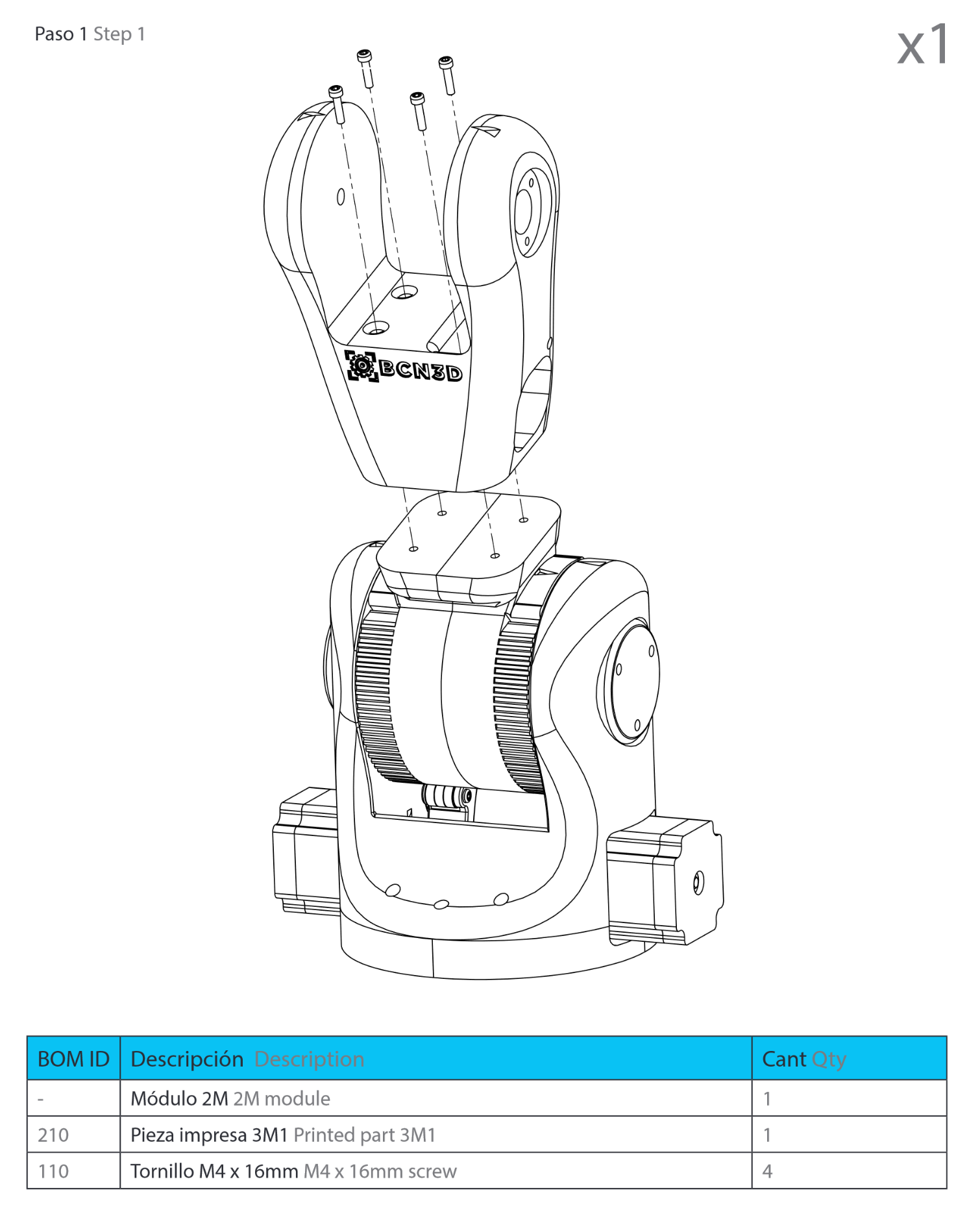

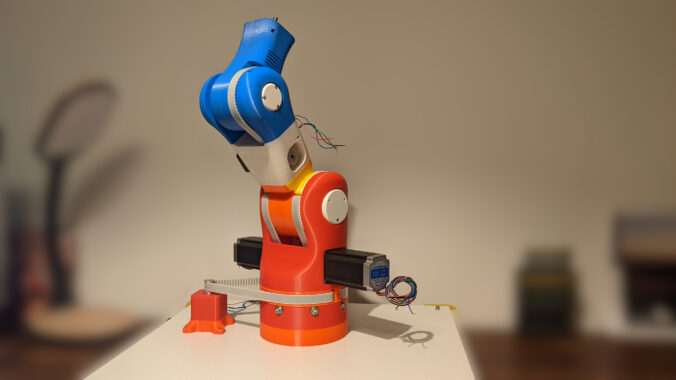

Step 1: Mount 2M1

The screws in the 1M1part a lose. I had to hold them with some tooth sticks into place. Then I mounted the 2M1 part on top of this.

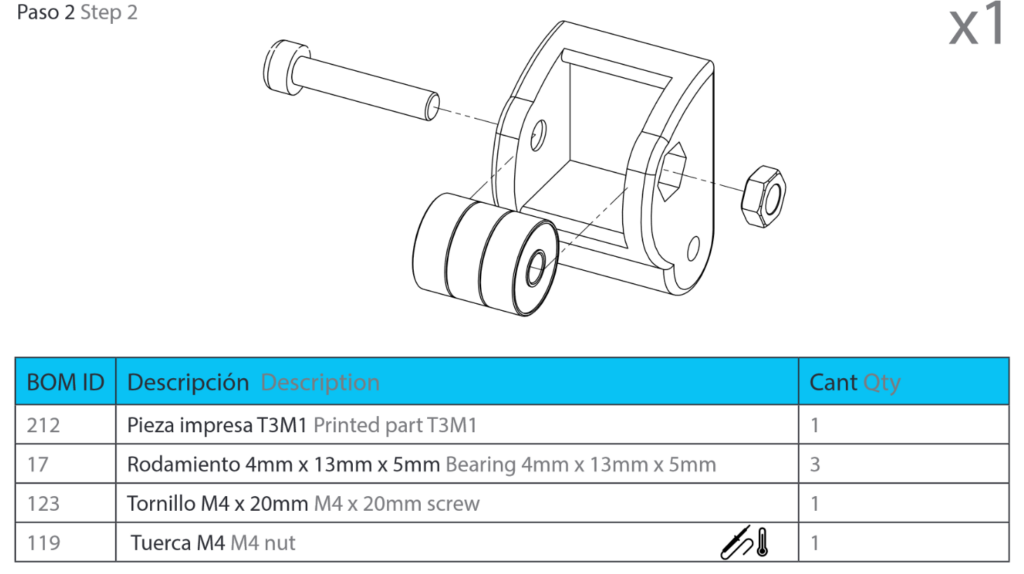

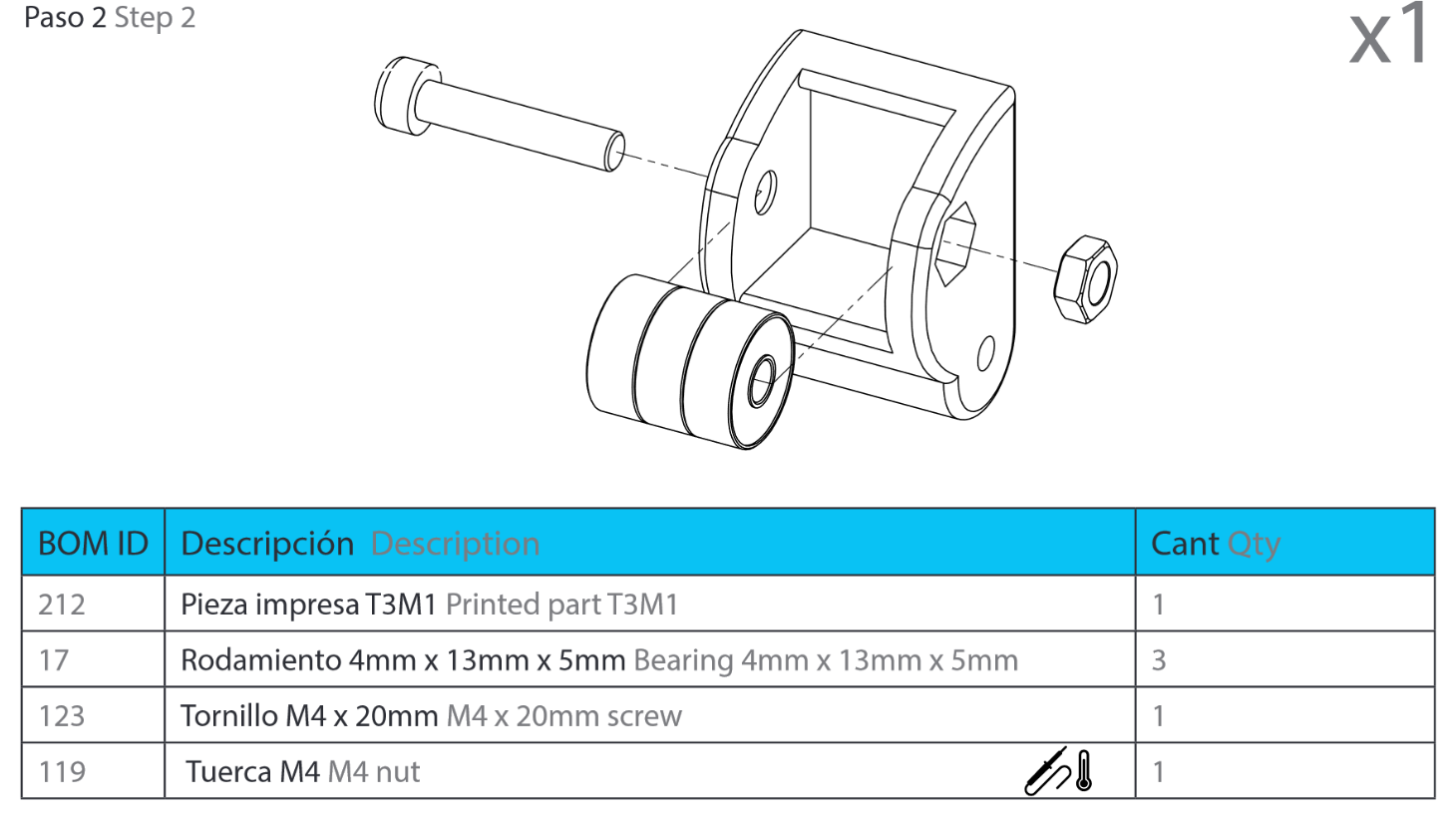

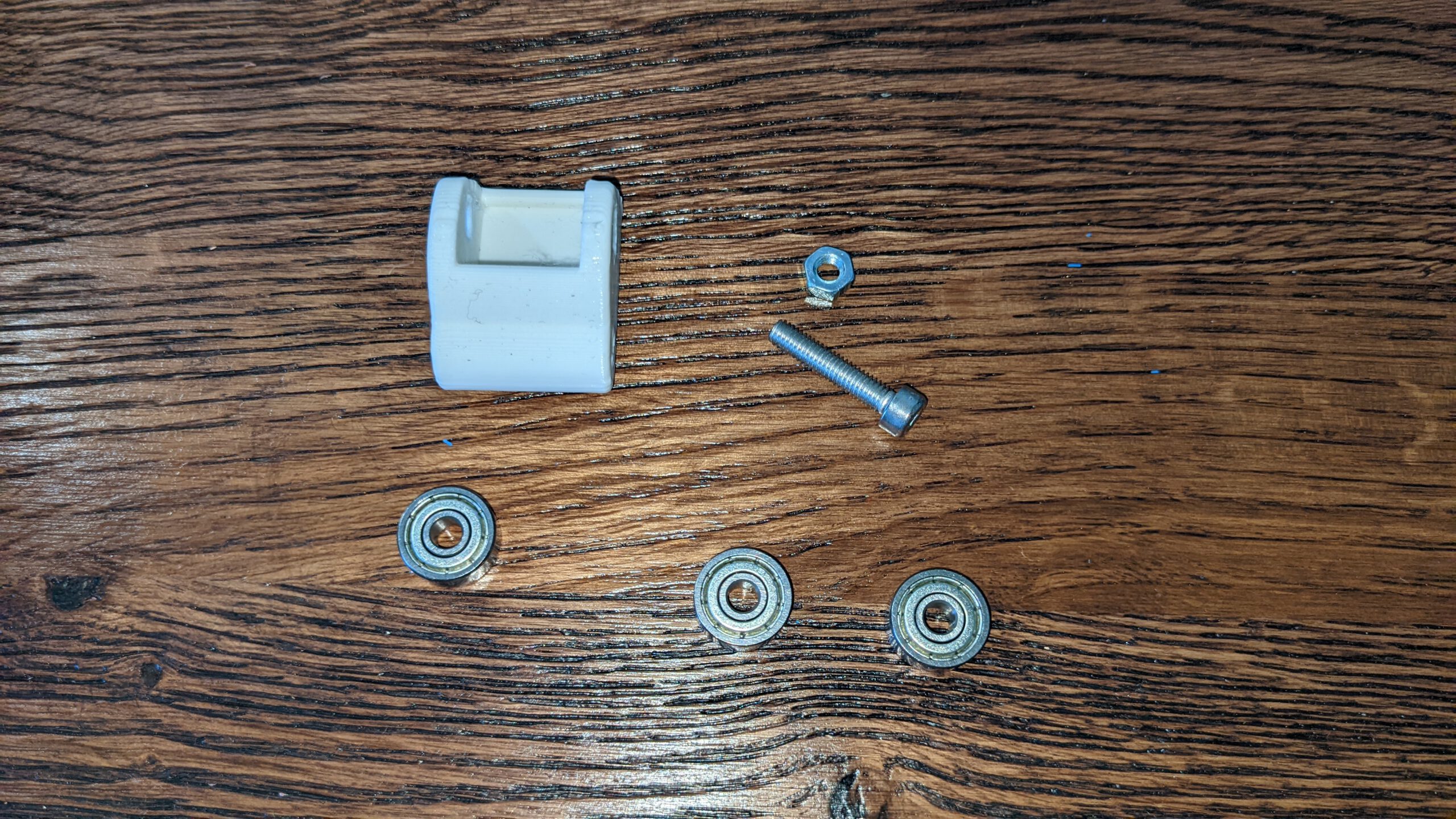

Step 2: prepare the belt stretcher

This time, my printer could handle the hexagon hole. I did not have to modify the printed piece.

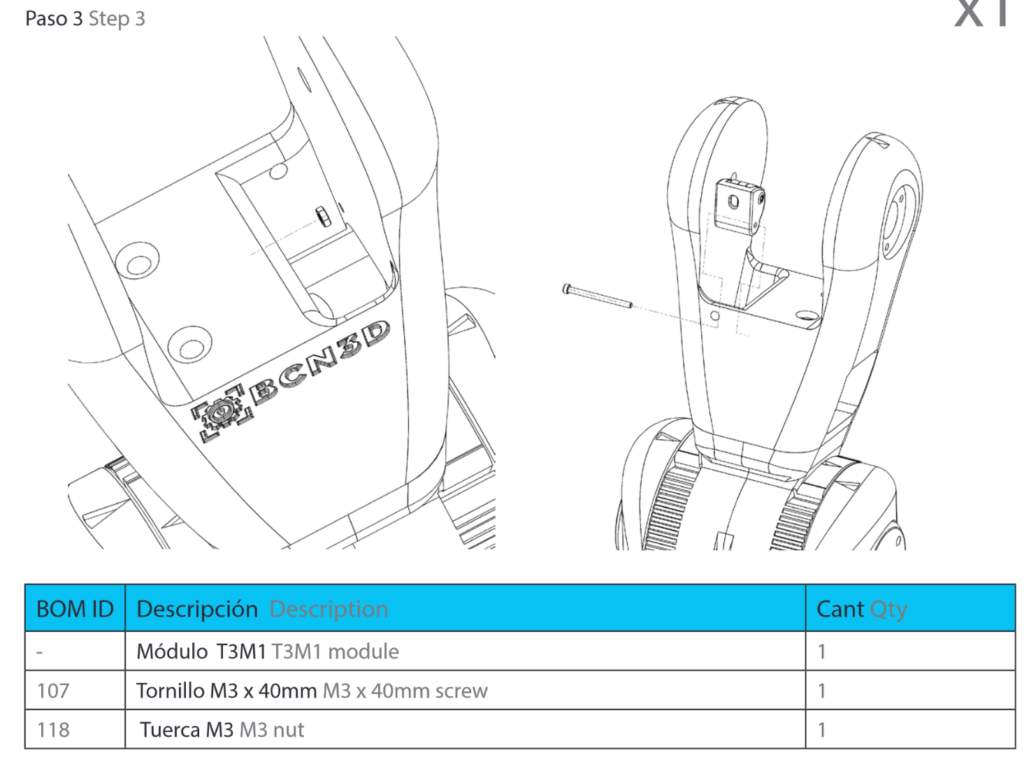

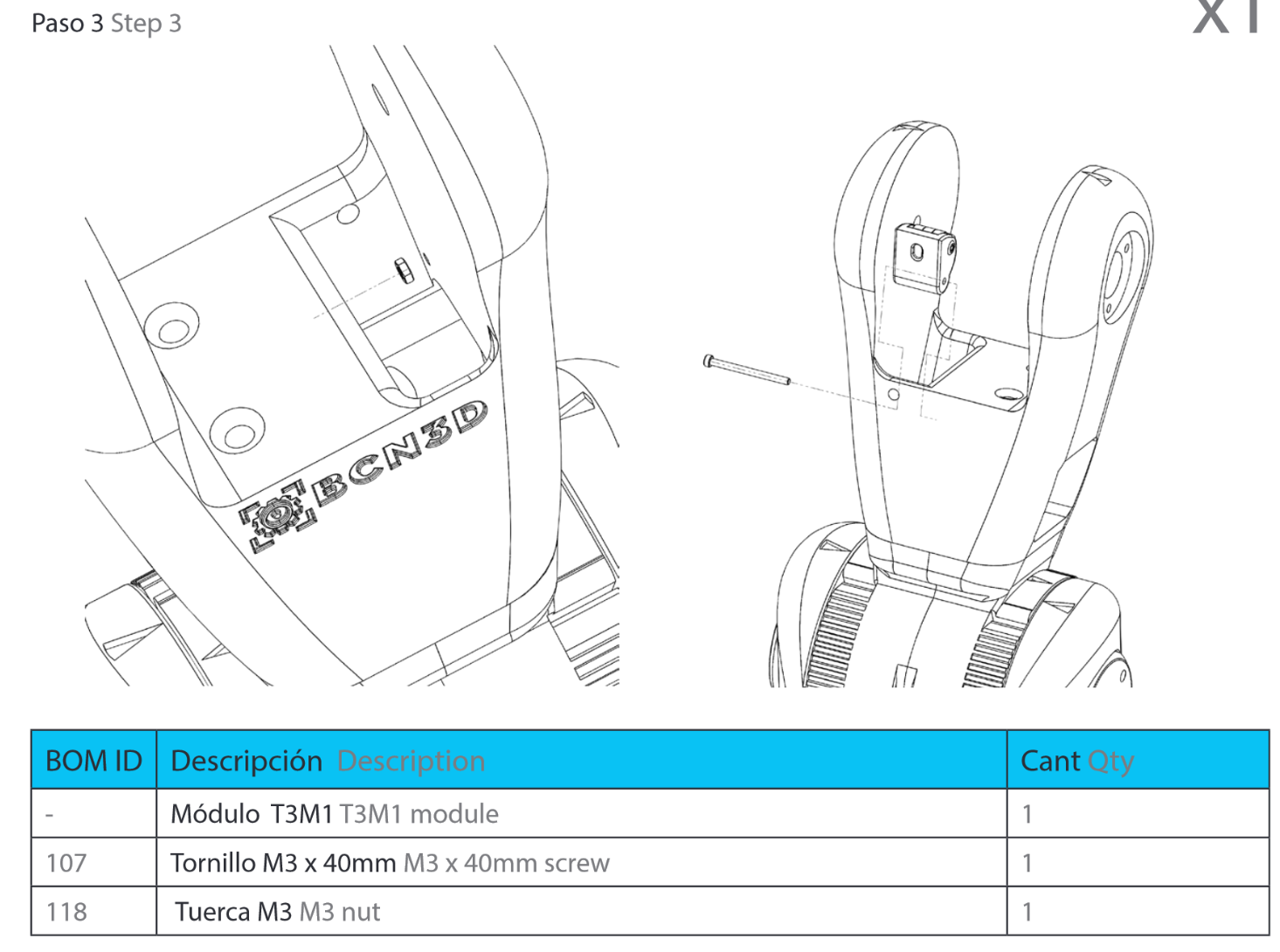

Step 3: Mounting the belt stretcher

The M4 screw inserts didn’t fit here, either. I had to glow them in again.

In the future, I have to find the correct inserts but for now, this is the way I’ll do it

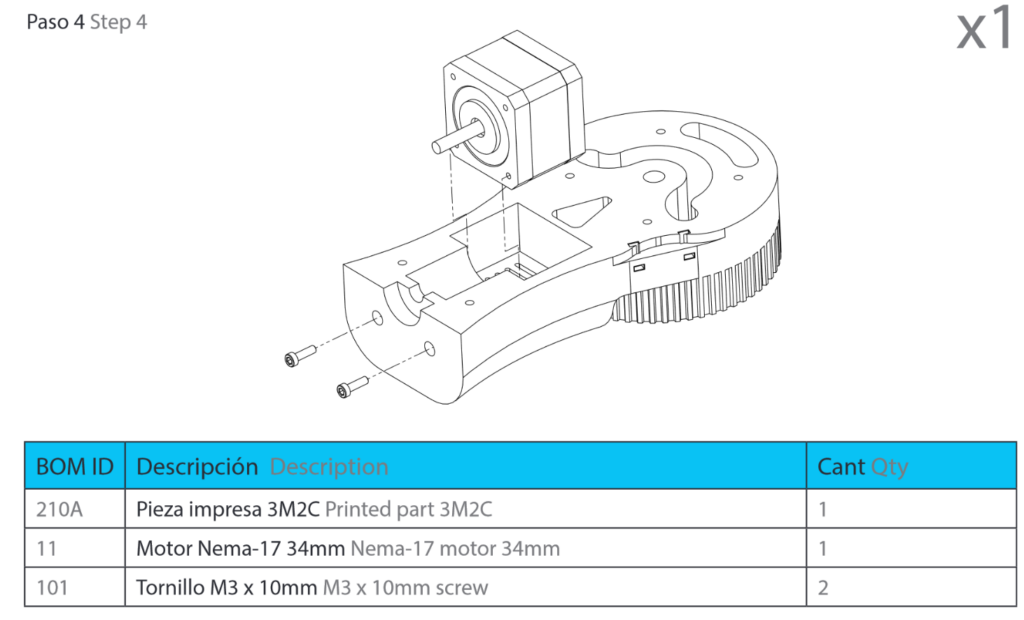

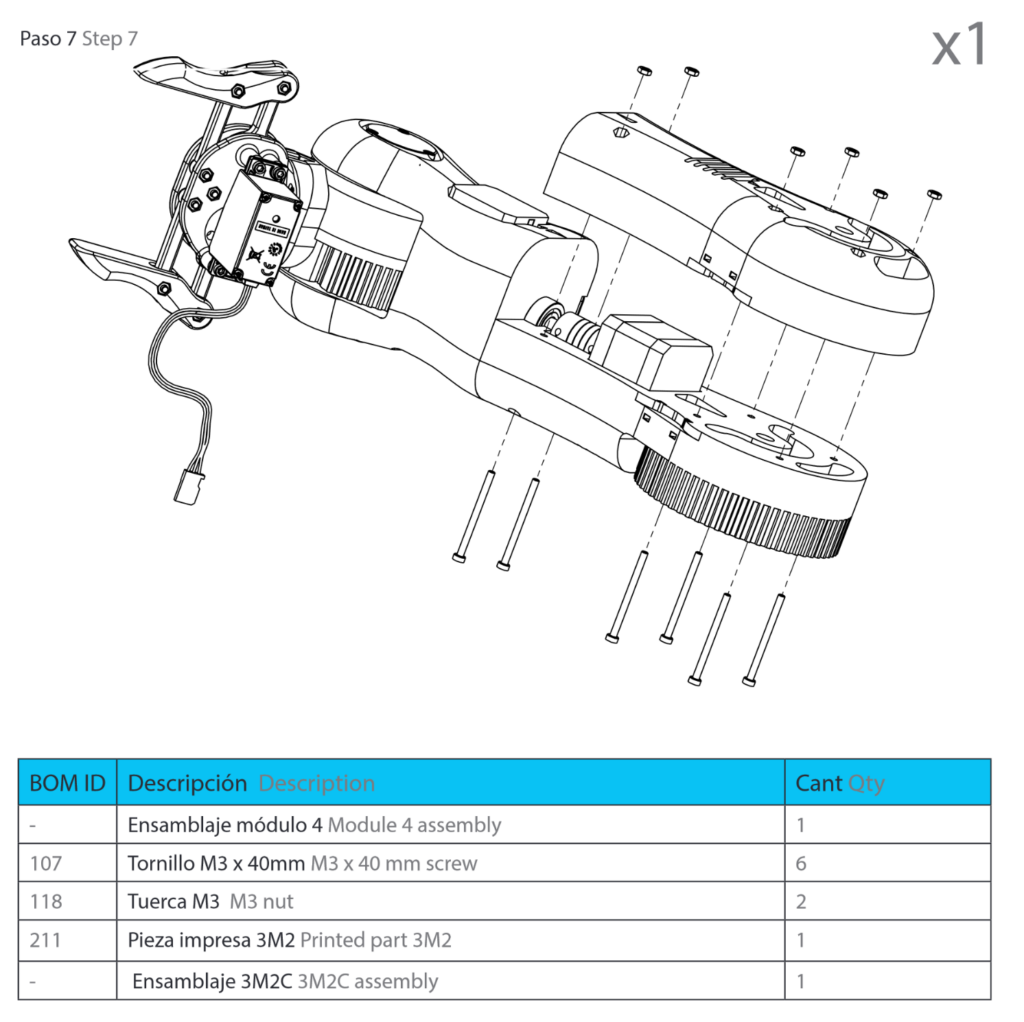

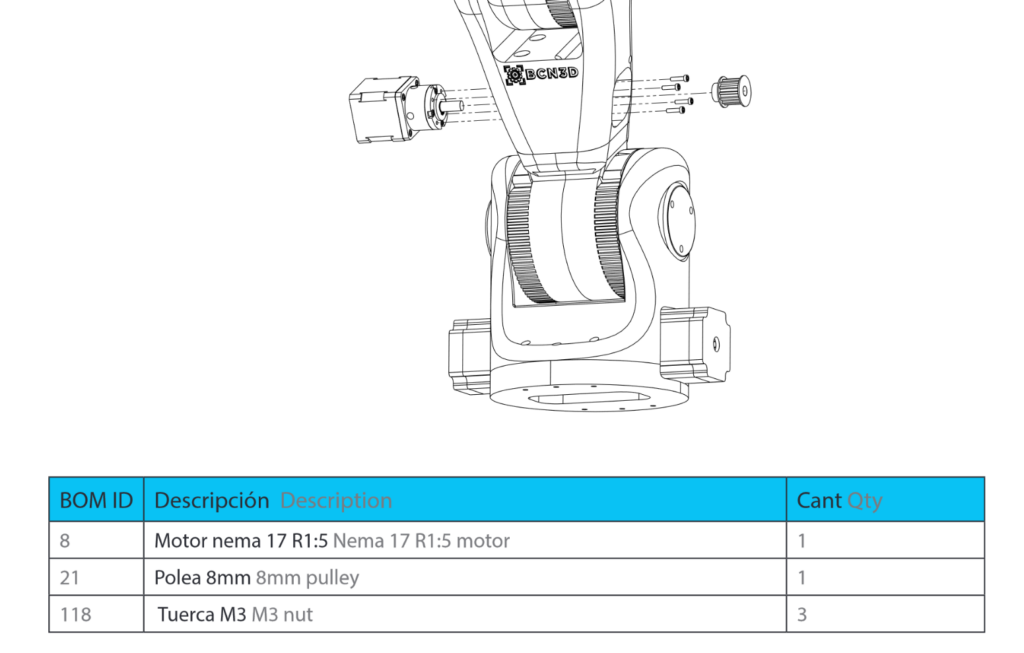

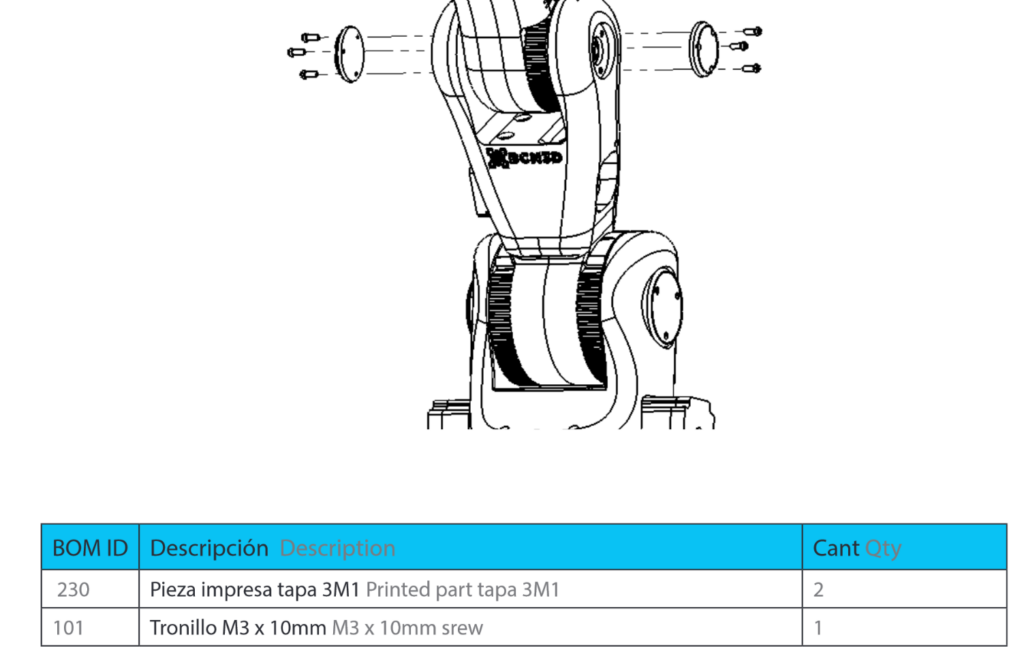

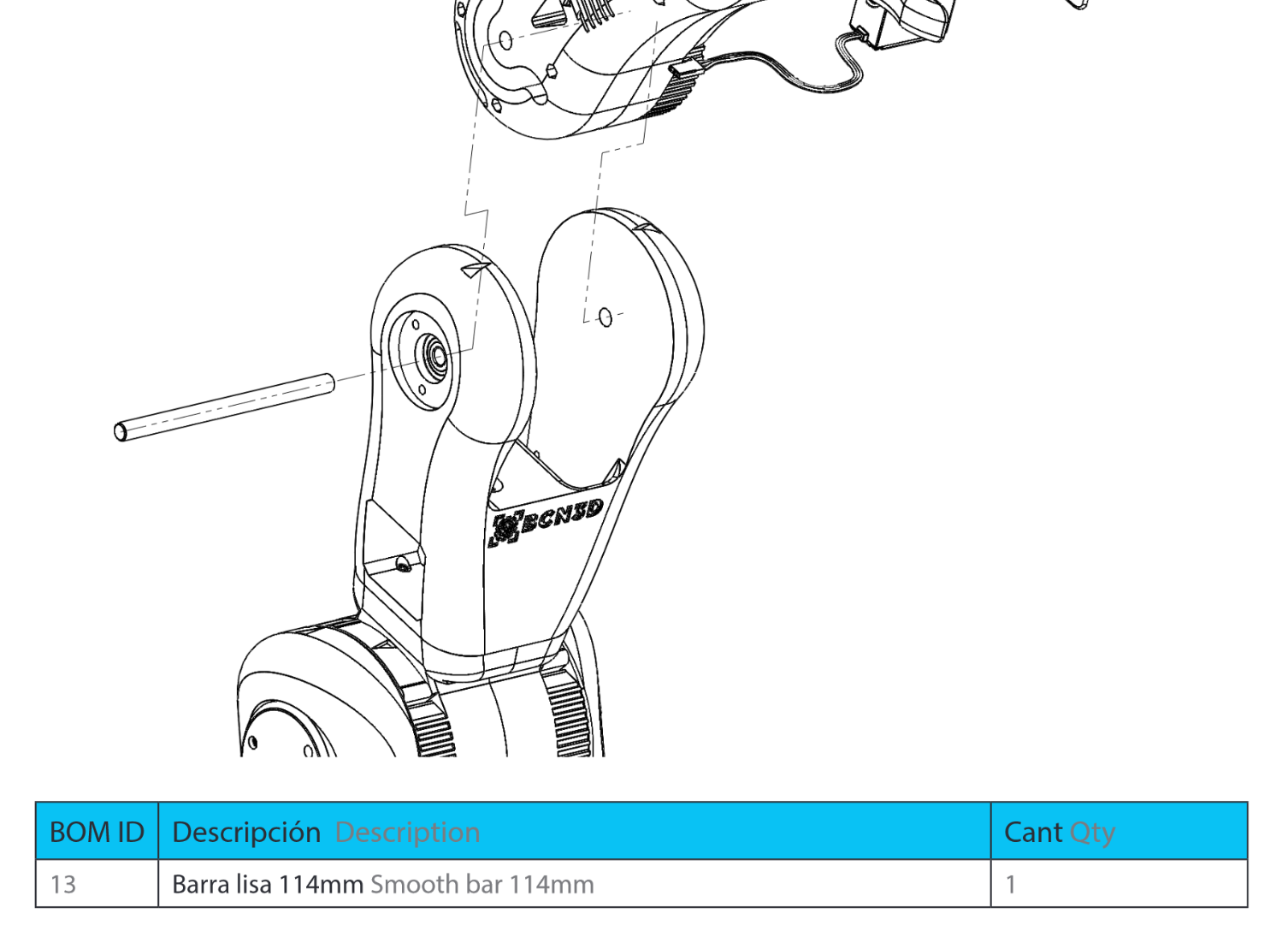

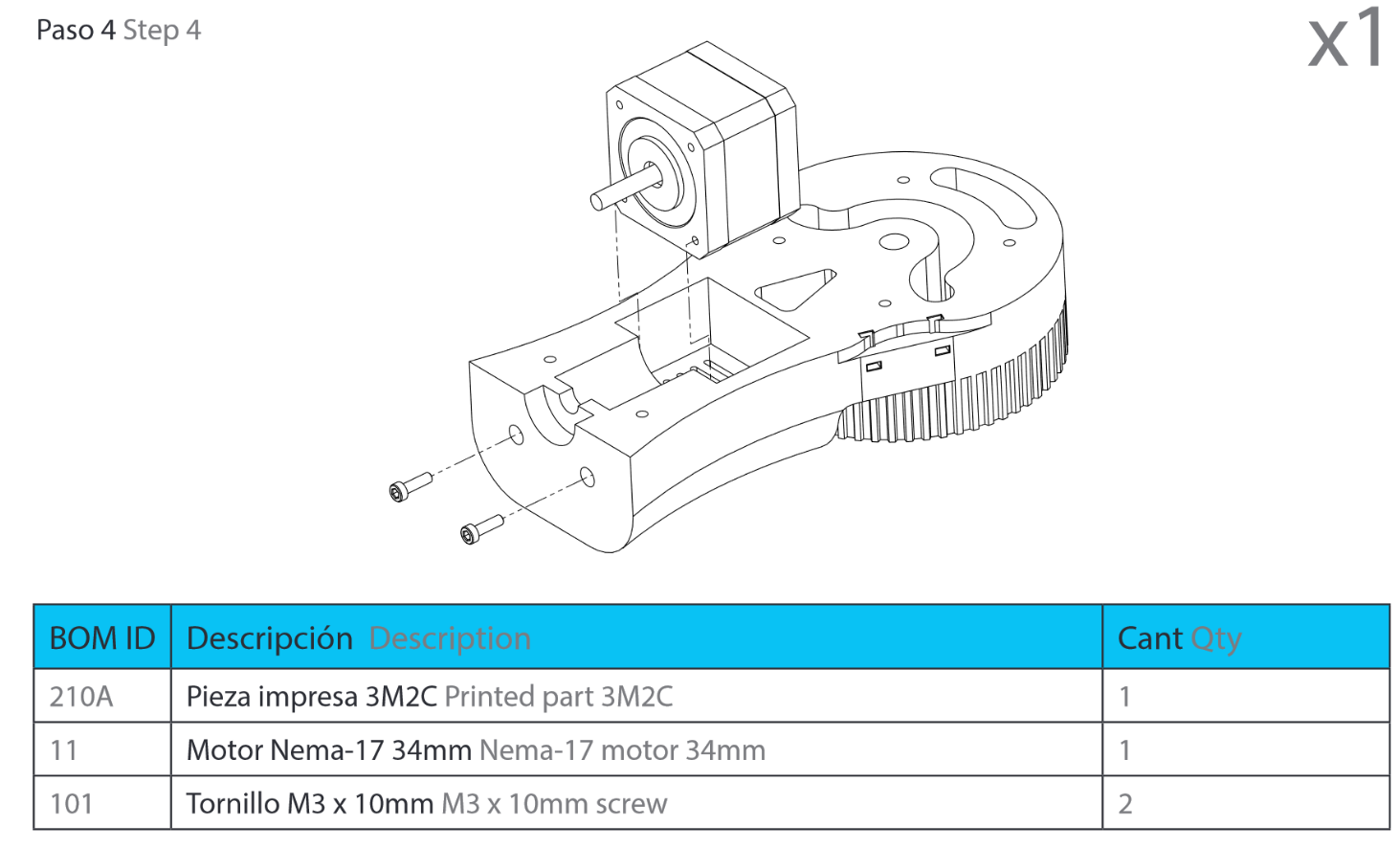

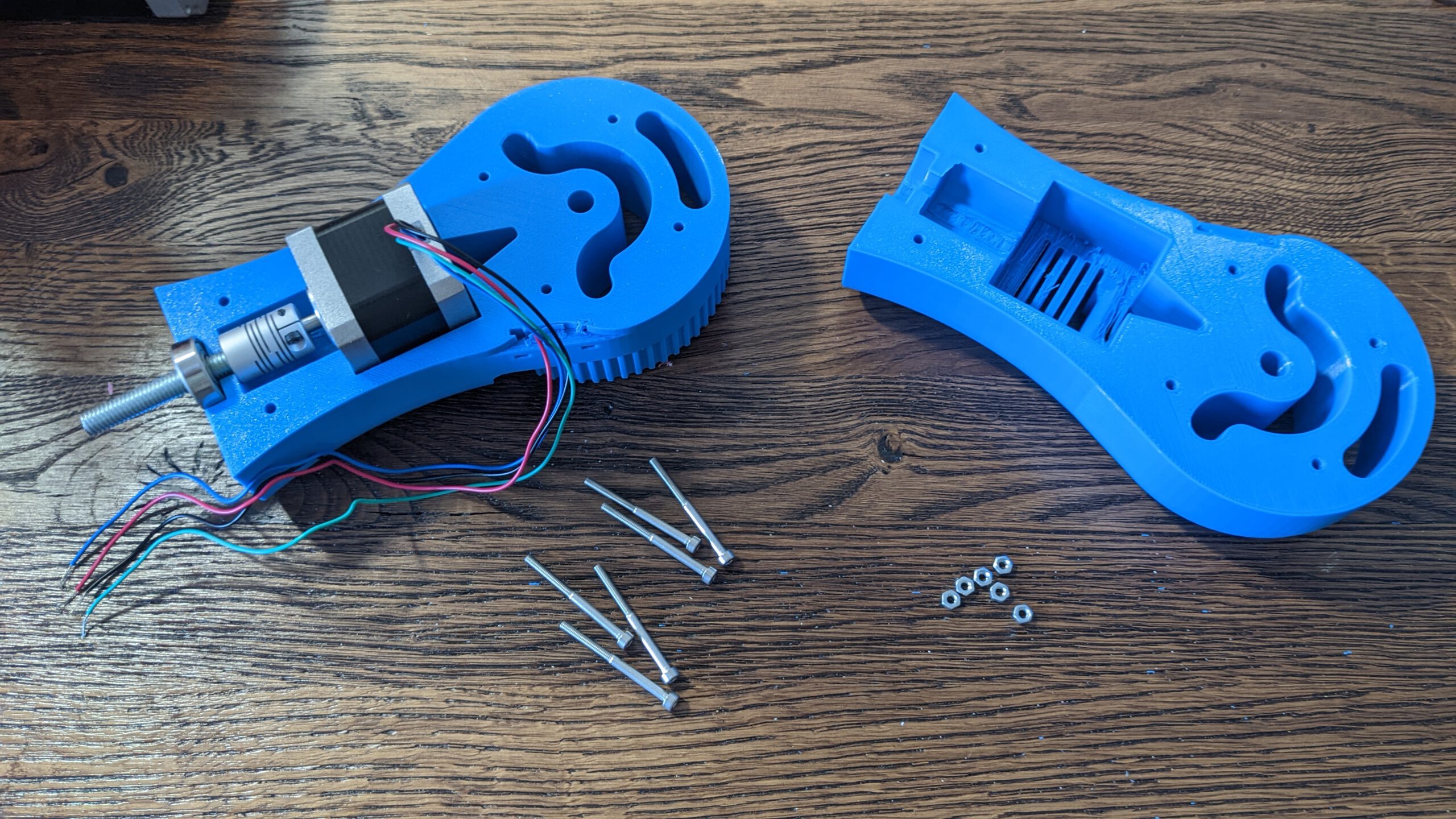

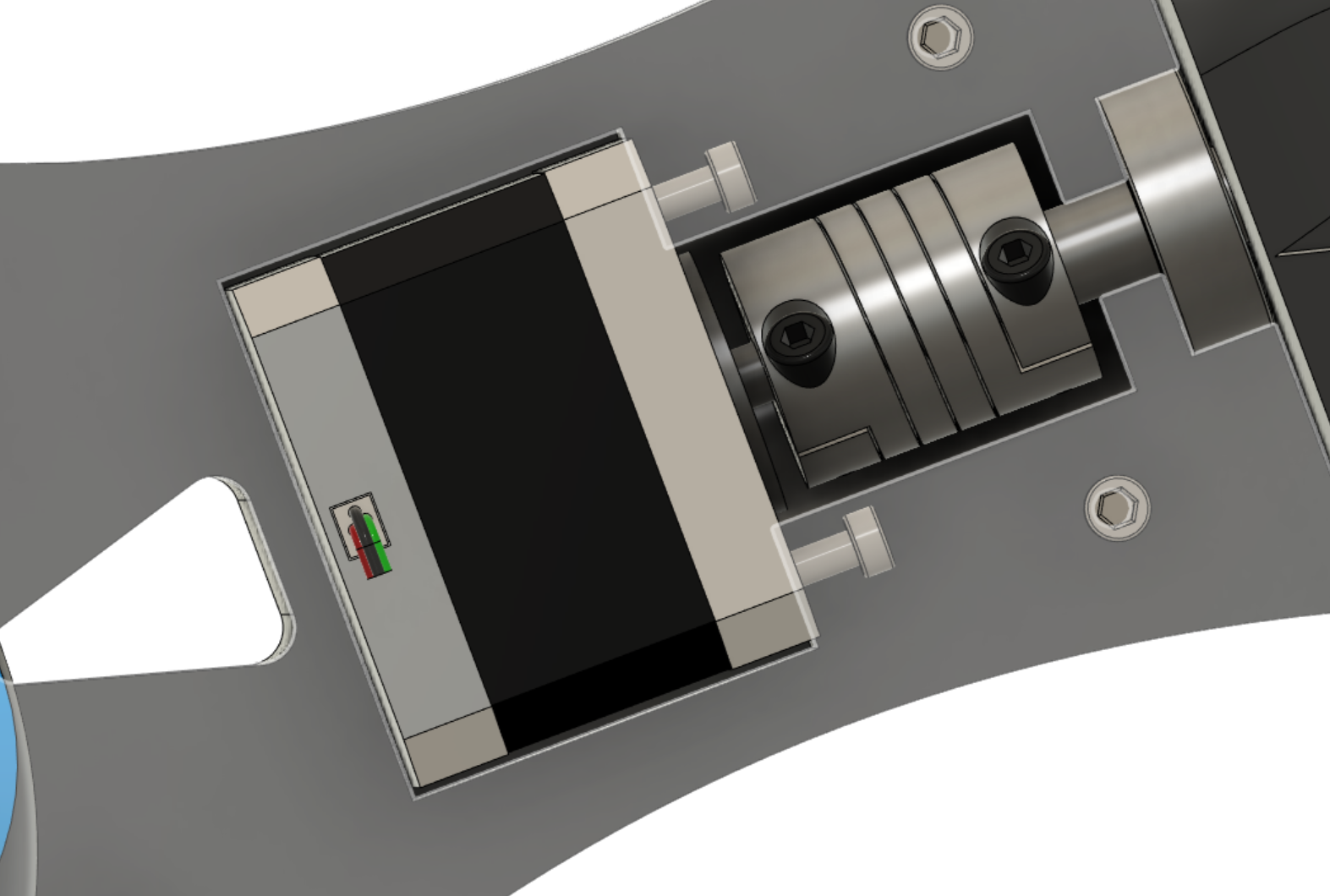

Step 4: 3M2 Assembly

We have edited the 3M2 parts (3M2C & 3M2CC) to fit our stepper motor inside. For the detailed changes, have a look at hit blog post:

Unfortunately I have not time to finish this week’s blog post in time. I take this week off and I will describe the second half of the post in next weeks blog entry.

Leave a Reply